Gebr. Pfeiffer sets up gypsum grinding-drying plant for Siniat GmbH within only 2 weeks for switchover

To maintain state-of-the-art standards, Siniat GmbH has set up a new gypsum grinding-drying plant in their Hartershofen works in Germany in close cooperation with Gebr. Pfeiffer SE. As stipulated in the contract, the new roller mill of the type MPS 160 B had to be integrated into the existing gypsum works in a way that the latter could remain in full operation until 2 weeks before the planned switchover from old to new. This challenge meant a great amount of sophisticated coordination work, project management, and engineering that Gebr. Pfeiffer was able to meet within the very short time schedule of 8 months as requested by the customer who was fully satisfied with job.

High demands set out in the contract

Siniat GmbH, member of the Belgian Etex Group, is specialized in dry construction materials and system solutions made of gypsum plaster and cement. Since 1991 a vertical roller mill of the type MPS 125 A has been operating in the Hartershofen works taken over by Siniat. This mill was used for grinding and processing natural gypsum, flue gas desulfurization gypsum, and recycled material to obtain the basic material needed for the production of plasterboard products

Siniat aimed at reducing capital expenditure for the rebuild to a minimum and keeping the production stop as short as possible. The new mill of the size MPS 160 B was to be set up next to the existing mill so that the latter could stay in operation while construction work was going on. The intention was to switch over from the old mill to the new one within 2 weeks during a maintenance stop.

This was quite an ambitious goal that Pfeiffer promised to achieve in the contract concluded with Siniat GmbH. Further requirements had also to be met: observing the tight time schedule of only 8 months between concluding the contract and commissioning, ensuring plant reliability, and handing over the overall grinding plant on a turnkey basis with all components from one source.

Project handling: focus on engineering

To ensure proper project handling, Gebr. Pfeiffer could rely on its long-term experience with the design and construction of tailor-made grinding solutions: the planning of the entire plant, the installation of all components, and finally the commissioning of the plant should be carried out without putting the ongoing production at risk.

Scope of the project at a glance:

- Specification and procurement of plant components

- 3D laser picture of the existing plant for planning how to integrate the new mill

- Planning, construction and turnover of the turnkey solution

- Planning of power supply, control system, and lightning

- Planning and laying/setting up of foundation and structural steelwork

- Structural analysis of the various lots

- Preparing the documents to be submitted to authorities according to the German Federal Immission Control Act (BImSchG)

- Entire plant electrics including electrical engineering, e.g. switch cabinets, drives, lightning, and process control systems

As is often the case with brownfield projects, the space available for setting up the new mill was very limited in the Hartershofen works. Moreover, various components of the existing plant should be used in the new plant after the switchover which was an additional challenge. Therefore, Pfeiffer started with a stock taking of the existing plant, using the millimeter precision of laser technology, and creating a 3D CAD model. With this method it was possible to do a precise layout planning of the new grinding-drying plant considering all interfaces and new components within the 3D CAD model.

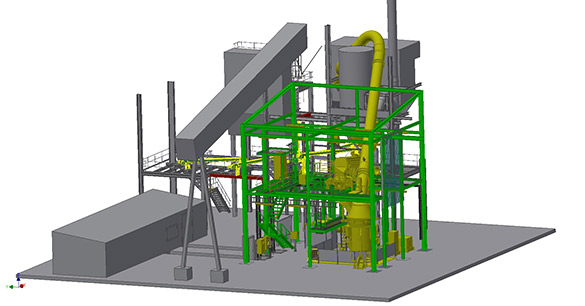

Hence this model did not only show the new vertical roller mill of the type MPS 160 B along with its components rotary lock, classifier and hot gas generator, but also the entire ductwork and connections as needed for the envisaged switchover. Upon arrival on the site, the above components were set up next to the old mill while existing plant parts such as supply and removal equipment, metering devices, plant filter, plant fan, and plant silo remained in operation just like the old mill.

3D CAD model for planning the rebuild: new structural steelwork shown in green, new plant parts are yellow, existing plant is grey

The decisive phase was reached when the new mill, structural steelwork, electrics, and control system had been completely set up. Now the old mill had to be stopped, all ductings connecting the new mill with the existing plant parts had to be laid and the plant silo had to be shortened at its lower end and provided with a proportioning belt scale. Thanks to the accurate planning work, the reconnection measures could be carried out within the 2 weeks as stipulated, without causing any major production loss, and the new plant was fully operational after only 8 months.

Bad surprise during laying of foundation

When laying the foundation, an unknown sewage pipe was discovered. It ran across the foundation and it would have been expensive for the customer to relocate it. Hence a solution was needed and found rapidly: the foundation was modified together with the structural engineer and the inspecting structural engineer so that the sewage pipe could remain in place.

Going on with the proven Pfeiffer mill technology

The rebuild with the new MPS vertical roller mill has turned the gypsum grinding-drying plant into a modernized system operating even more energy efficiently and reliably. Moreover, this rebuild was carried out while production was continuing, without any major production loss. The old mill had reliably operated for 25 years and the customer is convinced that his capital expenditure for the new MPS vertical roller mill will pay off for at least the same length of time.