Dry preparation of ceramic raw materials

Dry preparation of raw materials is an important field in the ceramic industry. Decisive factors for the success of any further processing steps and for ensuring envisaged properties of the baked final product are homogeneity, fineness, and the sorting out of adverse ingredients from the raw materials. Increasing quality requirements and rising cost pressure call for efficient processes. The sustainable solution to this challenge is dry raw material preparation in continuous, automated operation. We conceive and build complete preparation plants and offer individual machines from our wide range of products which are perfectly suited for your particular application. Pfeiffer set the benchmark for dry preparation of ceramic raw materials. The ceramic industry has trust in the work we are doing.

Details on raw material

Ceramics have been part of the everyday life of human beings for thousands of years, not only in the domestic area, but also in the construction sector. During the last century, technical applications have become more and more important. Nowadays, the ceramic industry comprises the production of tiles, roof tiles, ductwork, floor tiles, crockery, sanitary ware, refractory ceramics, and technical ceramics. The natural raw materials used for the production are clay, kaolin, quartz, feldspar and so on.

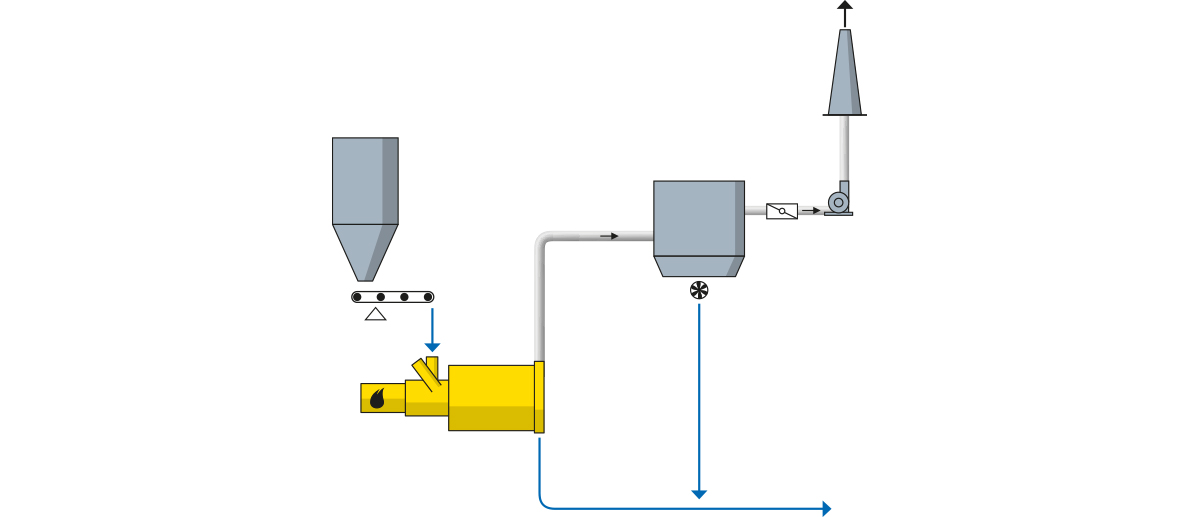

Drying

Lump-size ceramic raw materials like clay, kaolin, quartz, feldspar, etc. are dried in Pfeiffer Triplex dryers to the required residual moisture. The products obtained can be further processed in grinding plants, separated in classifying systems or used directly in plastic forming.

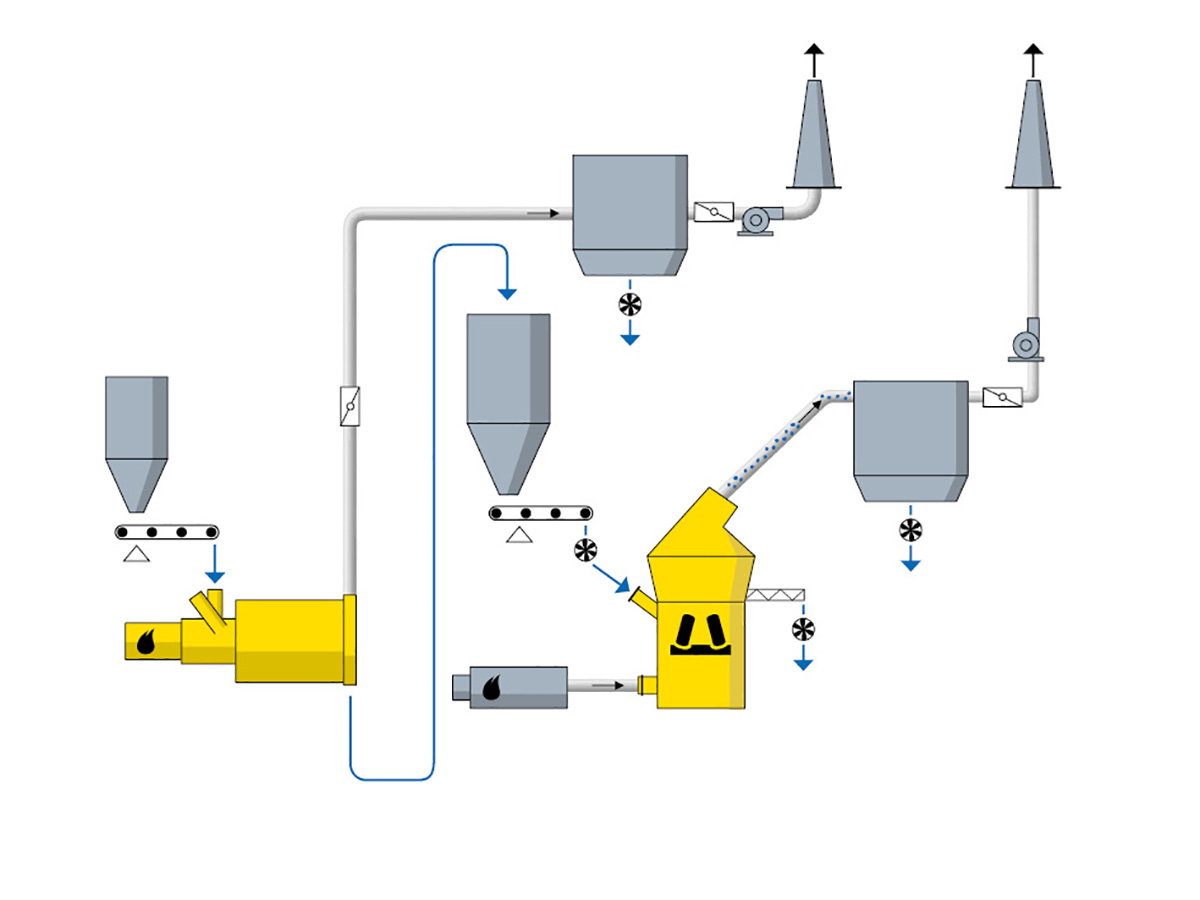

Grinding-drying

Lump-size ceramic raw materials of low to medium abrasiveness are ground, classified, and dried in Pfeiffer MPS vertical roller mills. The fineness of the finished products can be set within wide limits (0.02 to 0.5 mm). If required, adverse ingredients contained in the raw materials can be separated out during grinding and discharged from the mill. If raw material moistures exceed 12%, a Triplex dryer is provided ahead of the mill so that the material can be predried which is more cost-efficient. The ground and pulverized products are used as basic material for the production of ceramic working masses and mixtures needed in the sector of coarse and fine ceramics. The raw materials, which are often not homogenous and due to their geological origin have different chemical and physical properties, are homogenized as a result of grinding.