Individual solutions ensuring optimum results

Modernization projects which call for the integration of grinding plants into limited areas within existing cement works are one of the topics Pfeiffer engineers deal with in their everyday work but they also handle projects for the implantation of grinding plants in completely new cement works or separate grinding terminals. No matter what type of project is concerned, the basic idea is to meet individual requirements. This is what we do by optimally adapting our products and processes to the prevailing conditions. Cements consisting of the components cement clinker and gypsum and maybe also additional extenders can be ground in common, but the materials (like clinker, granulated blast-furnace slag, limestone, sulfate carriers) can also be ground separately for being mixed after having been finely ground.

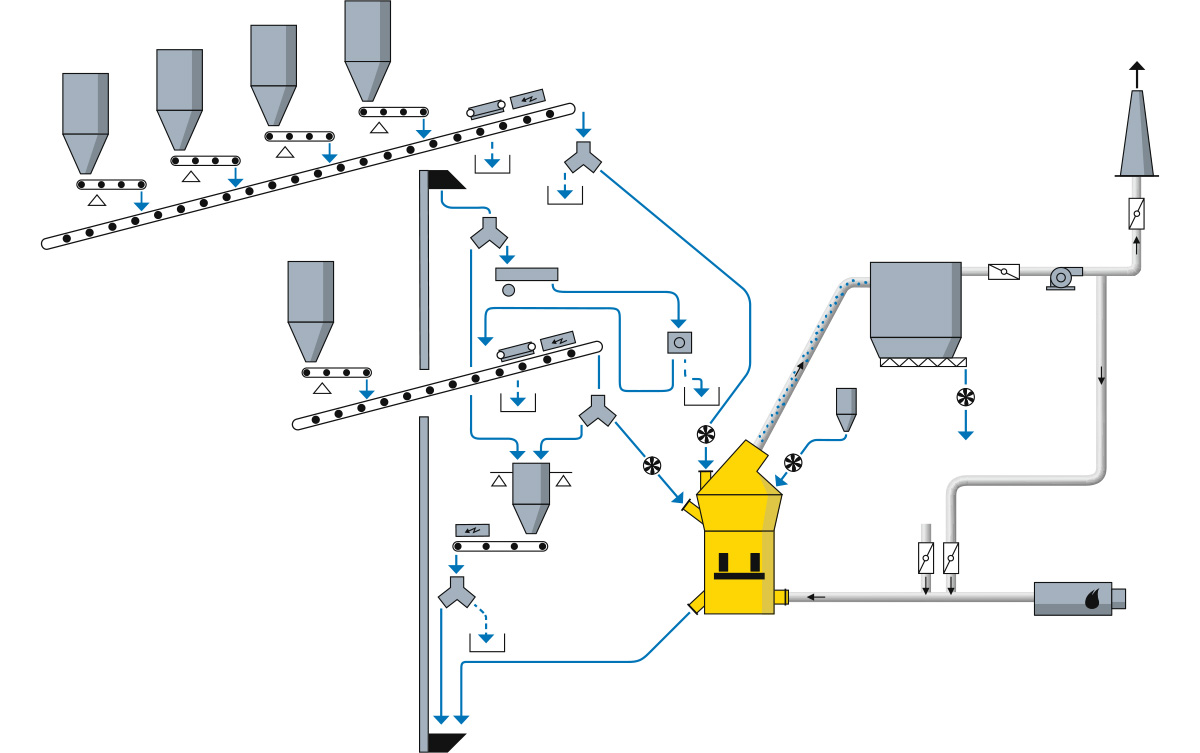

What we also do is to discharge undesired material like metallic components and prevent extenders which already have the fineness required, e.g. fly ash, from being reground unnecessarily. In this way our plants remain as compact as possible, thus reducing capital expenditure significantly.

Details on raw material

Cement clinker is produced on the basis of a raw material mixture which is sintered in a kiln system at more than 1400°C. As a result, compounds form – the so-called clinker phases – which are specific calcium silicates and calcium aluminates. These ensure the characteristic properties of the cement during hydraulic hardening. The so produced cement clinker is ground together with gypsum and/or anhydrite, thus forming the final product cement. Depending on the availability of the raw materials and market-specific requirements, further extenders are added to the common grinding process such as granulated blast-furnace slag. Mainly consisting of lime, silica acid, aluminum oxide, and magnesium oxide, blast-furnace slag is normally processed in granulation plants nowadays. By quenching the liquid slag, a glassy, granular product is obtained, the so-called granulated blast-furnace slag which is particularly suited for use as an extender in the production of high-quality cements.

Grinding of cement and/or granulated blast-furnace slag – Material separation in the filter

The cement components are ground, dried, and classified in the Pfeiffer vertical roller mill. Moist feed materials can be fed to the mill separately from warm and dry feed materials. Product quality and product fineness can be adjusted within a wide range (up to 6000 cm2/g Blaine). The ground and dried products are separated from the process gas by a dust collection filter which is followed by a fan. Downstream of the fan, the gas volume flow is divided: part of it flows back to the mill, the remainder is evacuated through an exhaust gas chimney. The mill is equipped with an external material recirculation allowing the reduction of pressure loss in the mill. It can also be used for emptying the mill in case of maintenance. When grinding granulated blast-furnace slag, the iron particles contained in the slag can be discharged.